Playing with my new mini wood lathe has been fun. You do have to change the pulley frequently as you go from roughing to shaping to sanding your project. As I was informed in the product reviews there was a process to changing the pulley on the Excelsior Mini Wood Lathe. Removing and replacing the pulley covers took some time.

Wood Lathe – Original Set Up

The two access panels, (one on the back of the head stock and the other on the end), have two screw knobs. The handle is in the middle. While the locking screw is at the top of the plate and takes a bit of time to screw out or in as you are removing or replacing the pulley cover. Getting the screw to center in the screw hole was a challenge on the back of the wood lathe. This is the lower pulley cover on the end of the lathe.

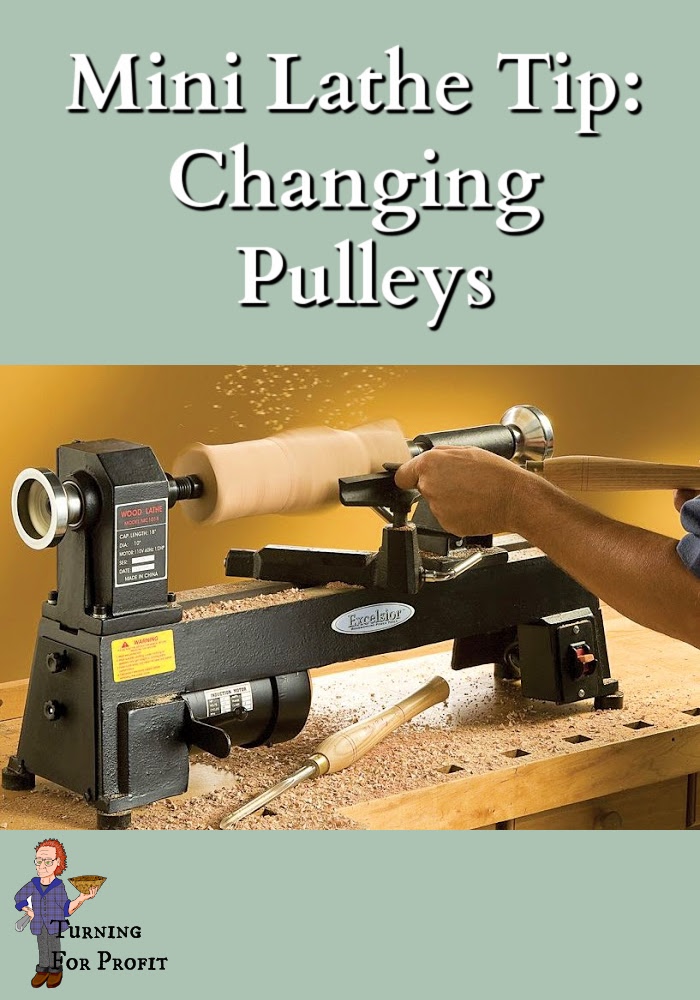

Wood Lathe – Adaptation

Remove the locking screw completely. Attach two rare earth magnets to the cover. The body of the mini wood lathe is cast iron so the magnets will have metal to attract them. I used 3/8ths inch rare earth magnets and attached them with scotch tape. Do this on both pulley covers. As you can see the magnets hold the cover in place.

Wood Lathe – How to Use

Now to remove the cover you simply grab the handle and lift. To replace slide the slots on the bottom of the plate over the respective screws on the lathe and the rare earth magnets hold the cover in place.

Wrap It Up

This simple tip will enable you to remove and replace the pulley covers easily with one hand. No more fiddling with the locking screw and having to have the plate in the right position to find the screw hole. I am going to adjust my set up slightly by buying four 1/2″ rare earth magnets and using super glue to hold them in place. So far the smaller taped magnets are working great. I rough turned a bowl and a face plate chuck that increased the vibration of the lathe. The covers stayed in place with no problems.

I would also check occasionally to remove excess dust that might build up between the cover and the lathe. For actually changing the pulley the best tip I read was to always move the pulley to the smaller wheel first.

What tip have you got for improving the use of your wood lathe?

First, thank you for these wonderful articles. I am just starting a hobby/part time wood turning business and you are helping tremendously as a resource. One thing I have done that has helped me keep things in order, is I put a magnet on the front of lathe. It is large enough to hold my Allen wrench for the chuck, Jacobs chuck key, and any other small metal part that I use often and want to keep within reach.

That is a really good idea. Thanks for sharing.

Where is one of those dam pencils?

Lost again in the pile og wood chips

Tape or glue a small magnet to the top end of those pencils. Now just put them in plain sight sight and they stay there, till needed.